For orders and details please call 726-999-0231

How Does An ECM Work?

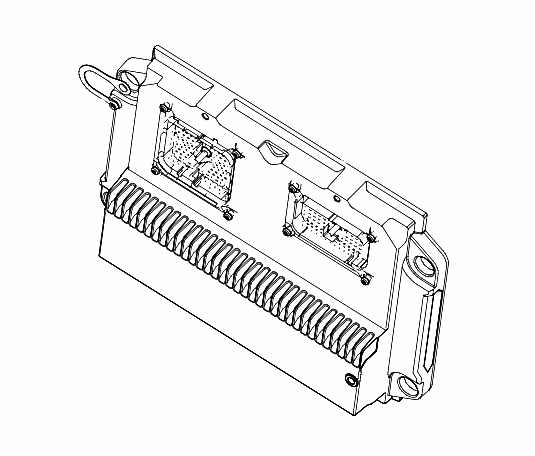

Also known as an ECU (engine control unit), the engine control module is the onboard computer on a vehicle that controls a series of actuators on the engine to ensure optimal performance. It achieves this by collecting data from numerous sensors positioned in the engine bay. The ECM interprets the information from the sensors using performance maps and adjusts the actuators accordingly.

Function

The ECM is responsible for controlling a multitude of crucial operations within an internal combustion engine. Here are a few of them.

Controlling the Air-Fuel Ratio

Most modern internal combustion engines deliver fuel to the cylinders through some type of electronic fuel injection system. It’s the ECM’s job to ensure the right amount of fuel is being injected. It does so by collecting and processing readings from various sensors.

For instance, the oxygen sensors tell the ECM whether the engine is running lean (too much oxygen/too little fuel) or running rich (too much fuel/too little oxygen) compared to optimal conditions (referred to as stoichiometric). There’s a throttle position sensor which tells the ECM how much the throttle plate is opened when the gas pedal is pressed down.

The amount of engine flowing into the engine through the open throttle plate is measured by the mass air flow sensor. The coolant temperature sensor measures how warm the engine is. If it’s too cool, the ECM sends the signal for additional fuel to be injected.

Controlling Idle Speed

The majority of modern engines come with ECMs that have built-in idle speed control. The crankshaft position sensors, which plays a vital role in the engine timing functions for spark events, valve timing, and fuel injection, monitors the engine RPM. The crankshaft position transmits data to the ECM, which then controls the idle speed through an idle air bypass control stepper motor, or a programmable throttle stop.

Control of Variable Valve Timing

In engines that have variable valve timing, the ECM is responsible for controlling the point in the engine cycle during which the valves open. Usually, the valves are opened sooner at higher speeds compared to lower speeds. This can increase the amount of air flowing into the cylinder, increasing fuel economy and boosting power.

What Causes an ECM to Go Bad

Due to exposure to the elements, an ECM can become faulty over time. Moisture and corrosion damage are two of the most common culprits behind failing ECMs.

Because it plays such a vital role in keeping your vehicle’s engine healthy, it’s important to replace it as soon as symptoms of failure appear.

CATECM is one of the United States’ leading providers of Caterpillar ECM replacement, repairs and reprogramming services. We deliver all over the United States and all our engine parts come with a 1-year warrant. Get in touch with us to learn more.