For orders and details please call 726-999-0231

ECM Remapping: How it Can Make Your Business More Efficient

Back in the 1990s, fuel efficiency for mining and construction businesses often meant having fuel tanks large enough to run for 12 hours straight. However, times have changed now. With diesel fuel prices averaging around the $3 per gallon mark, contractors are now realizing how much of an impact the fuel economy of their equipment has on margins.

Many businesses rely on machines to get the job done. Whether you’re in construction, mining, or trucking—chances are you’re relying on an engine to do the hard work. And in today’s challenging economy, there aren’t many businesses that can afford an inefficient operation.

Over the course of this blog post, we’ll discuss how ECM reprograms can help businesses slash costs and improve margins.

Standard Programming Equals Standard Performance

The problem is that manufacturers program ECMs to function in standard environments, based on assumed fuel quality and average climates. So, with standard ECM settings, your vehicle will be restricted by factors that don’t apply to you. Moreover, it’s common for manufacturers to use the same drivetrain and engine in different models. It’s just the ECM programming that makes them different.

Fine Tune Your ECM for Greater Efficiency

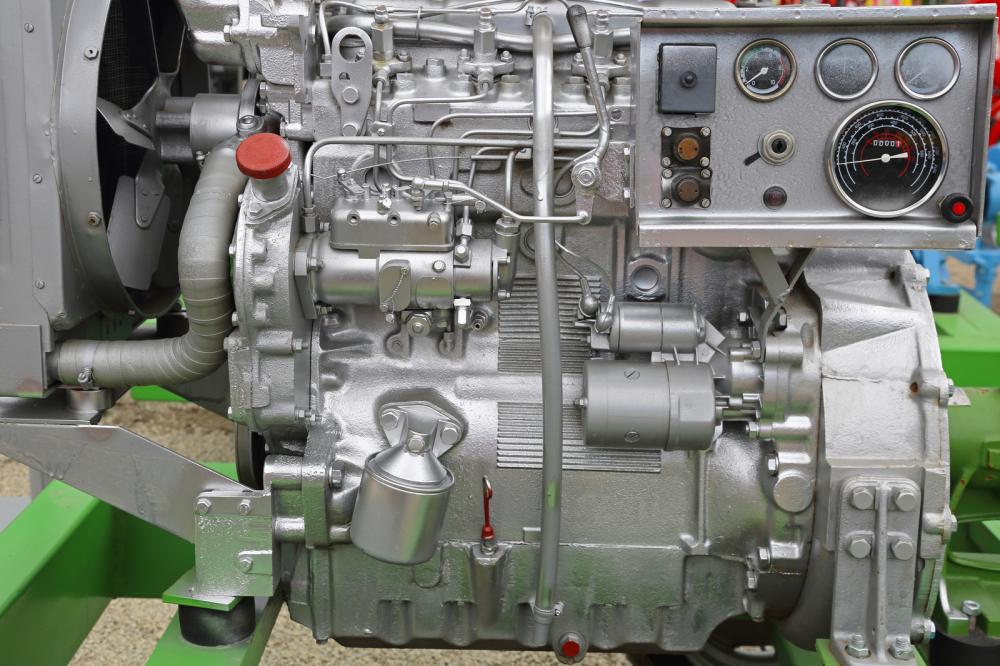

With an ECM remap, you can fine tine all the variable performance parameters of the engine so that it delivers optimal fuel-efficiency at all times. These performance parameters include the air-to-fuel ratio, the ignition timing, and the amount of fuel that’s being injected into the cylinders.

An ECM Remap Can Enhance Engine Performance

Improved efficiency isn’t the only thing you can achieve with an ECM remap. You can also reprogram a diesel engine ECM, so the engine delivers more power. The upshot of this is you get more output for less input. When your engines are producing more power, you can get more work done in lesser time., which will increase ROI and profits.

Get Your ECM Reprogrammed by a Certified Professional

While you can get significant performance and efficiency gains with a custom ECM remap, it’s a risky process. The standard firmware your ECM came equipped with is a delicately balanced system that is designed to ensure the engine stays reliable for years and years.

If you’re reprogramming your ECM with a custom software, make sure that is takes all the aspects of the engine performance into consideration. For instance, if you reprogram the ECM to only increase the power output by altering the compression ratio, it’ll have a drastic effect on the fuel economy and will cause the engine to wear out sooner.

Therefore, ensure that you get your ECM reprogrammed by a licensed and certified company.

When it comes to Caterpillar ECM replacement, repairs and reprogramming services, CATECM is one of the leading names in the United States. We also supply re-built parts manufactured by Caterpillar Inc and provide 1-year warranties with all our products. Get in touch with us to learn more.